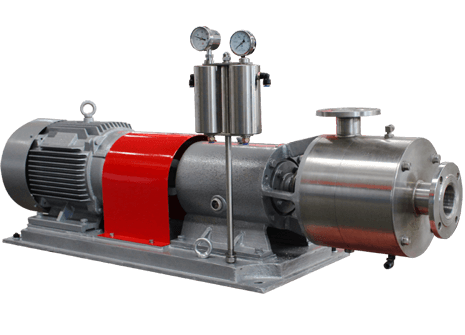

Inline mixers

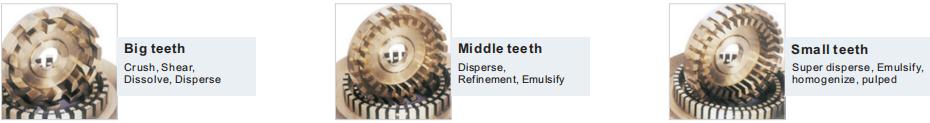

The high shear inline mixers working chamber is equipped with one set, two sets or sets of rotating stators, there are end suction ceilings and horizontal cantilever structures. Each level is two to six layers, and is composed of primary, secondary or three stage high speed rotating stators. The motor and the working head are elastically connected. The bearing can be greased or lubricated, it is easy to disassemble and install, and the cost of replacement parts is low. The double-faced mechanical seal is used. The applicable temperature is -20—140 degree celsius, and the temperature range needs to be customized.Models

working process

1. The high shear inline mixers is a high performance equipment for continuous production or recycling of fine materials. There are 1-3 sets of stator and rotor equipped in the chamber, it generates very strong axial suction power to draw materials into the chamber when the rotor runs.

2. After materials enter the chamber, it is quickly dispersed, homogenized and emulsified, and equably mixed.

Model Composition

(Note: Product category: C single-level six-story horizontal D second-level six-tier bracket type E three-level six-tier bracket type)

Applications

1.Biomedicine

Fat emulsion, vaccine, injection, antibiotics, medicated lotion, microcapsule emulsification, cell disruption, tissue homogenate, microspheres, etc.

2.Daily Product

Face cream, shower gel, shampoo, cream, skin lotion, make-up, cleansers, soap, daily fragrance, etc.

3.The food Industry

Liquid milk, milk drinks, dairy products, juices, ketchup, peanut butter, jam, ice cream, jelly, pudding, chocolate, soy milk, beer, seasonings, food additives, etc.

4.Petrochemical

Lubricants, heavy oil, diesel, asphalt, coal water slurry, catalysts, etc.

5.New energy

Lithium battery, lead acid battery, super capacitors, photovoltaic cells, etc

6.Textile Additives

Dyestuff, silicone, pastes, leveling agents, fabric finishing agents, brighteners, leather additives, etc.

7.Chemical Fiber

Slurry, spandex, kevlar, filament, staple, microfiber, viscose, high strength fiber, acrylic, etc.

8.Paints and inks

Printing inks, latex paints, architectural coatings, nano-coatings, coating additives, glaze, bentonite, pigments, etc.

9.Pesticide

Water emlsion, suspensions, microcapsules, seed coating agents, pesticide additives, insecticides, herbicides, fertilizers, etc.

10.Nano-materials

Fumed silica, ultra-fine titanium dioxide and ultra-fine alumina, etc.

11.Paper

Pulping, rosin dispersion, papermaking aids, rosin resin emulsification, paraffin emulsification, etc.

12.Fine Chemicals

Plastic additives, seasoning dispersion, adhesives, sealants, glues, surfactants, anti-sticking agent, fluorine cleaning agent, pigment paste, fungicides, flocculants, coagulants,silicon cleaning agents, lighting materials, etc.

13.Reaction Extraction

On-line reaction, micro reaction, on-line extraction, macromolecular synthesis, polymerization reaction, ultra-pure reaction, solid-liquid reaction, gas-liquid reaction, multi-phasereaction, etc.

Work Advantage

1.Large processing capacity, suitable for continuous online industrial production

2.High uniformity

3.Time-saving, energy-saving, high efficiency

4.Lower noise, stable operation

5.High quality consistency

6.100% of materials are processed

7.Materials can be recycling processed and transferred

8.Simple operation, easy maintenance

9.Automatic control is optional

Pictures